WA-200 Automatic Spray Guns For Metal

The WA-200 automatic spray gun is an advanced coating tool featuring automated operation. Designed to provide precise paint control and an even, fine finish, the WA-200 Automatic Spray Gun is efficient and suitable for a wide range of painting scenarios, providing a convenient, high-quality painting experience.

Product Description

Automatic Spray Guns For Metal

1.Introduction of WA-200 Automatic Spray Guns for Metal

The WA-200 automatic spray gun is a top-of-the-line painting tool that combines cutting-edge technology with superior engineering. The gun utilizes advanced automation technology to achieve highly accurate and stable painting operations. Its intelligent control system automatically adjusts the paint flow, pressure and spray angle according to preset parameters, ensuring optimal results with every application and greatly reducing human error.

2.Parameter of WA-200 Automatic Spray Guns for Metal

|

| Technical Specification |

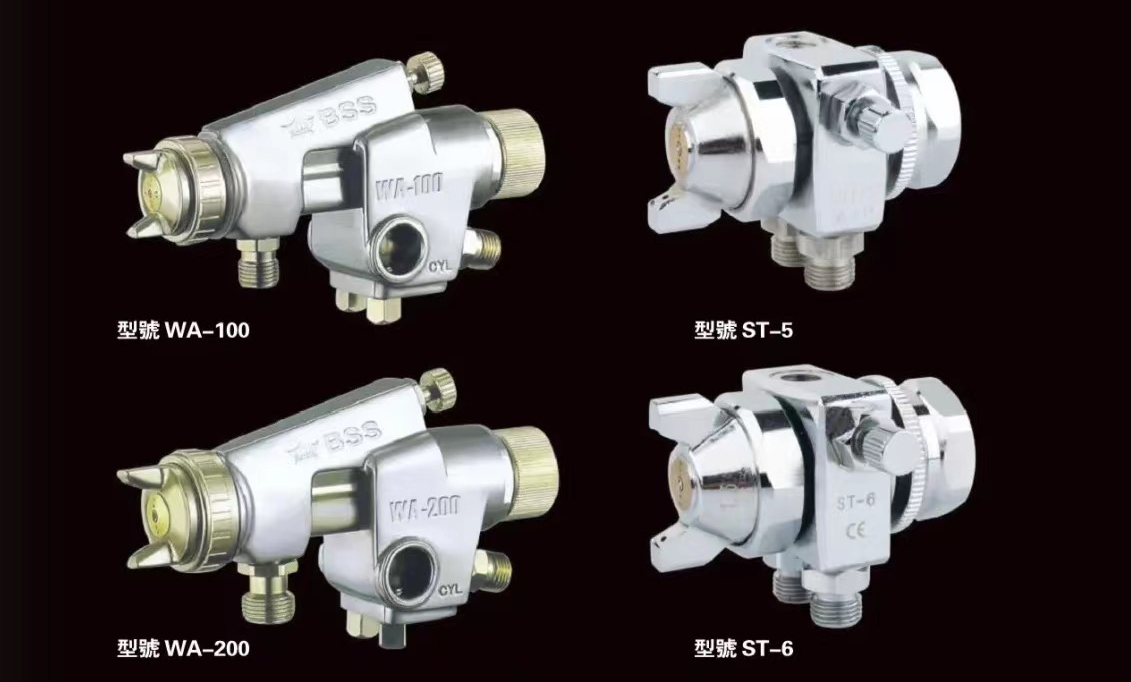

| Model | Coating supply system | Spray pattern | Paint nozzle diameter | Spray air pressure | Air usage | Paint discharge | Open spray | weight |

| φmm | MPa(bar) | L/min | ml/min | mm | g | |||

| ST-5 | Pressure feed | Sector and circle | 0.5 | 0.29(3.0) | 60 | 60 | 200 |

280 |

| 1.0 | 80 | 250 | 250 | |||||

| ST-6 | 1.3 | 100 | 360 | 350 | ||||

| 2.0 | 140 | 600 | 400 | |||||

| WA-100-P08 | Pressure feed | / | 0.8 | 0.29(3.0) | 270 | 150 | 190 | 480 |

| WA-100-P10 | 1.0 | 200 | 220 | |||||

| WA-100-P13 | 1.3 | 0.24(2.5) | 260 | 250 | 230 | |||

| WA-100-P15 | 1.5 | 270 | 245 | |||||

| WA-100-P18 | 1.8 | 190 530 |

310 | 240 | ||||

| WA-200-P12 | 1.2 | 0.29(3.0) | 500 | 400 | 548 | |||

| WA-200-P15 | 1.5 | 330 | 270 | 340 | ||||

| WA-200-P18 | 1.8 | 330 | ||||||

| WA-200-P20 | 2.0 | 360 | 400 | 320 330 |

||||

| WA-200-P25 | 2.5 | 500 |

3.Features

1. Highly automated

The WA-200 automatic spray gun is equipped with an advanced automated control system, which can accurately execute the spraying operation according to the preset program without frequent manual intervention, greatly improving the working efficiency and spraying consistency.

2. Precision Spraying

With high precision nozzle and flow regulator, it can realize fine control of spraying volume, spraying speed and spraying angle to ensure the paint evenly and accurately cover the target surface and reduce the waste of paint.

3. Outstanding atomization effect

Adopting unique atomization technology, the paint can be atomized into extremely fine particles to form a smooth, even and strong adhesion coating, which can achieve ideal painting effect on both flat and complex curved surfaces.

4. Durable and reliable

Made of high-quality wear-resistant materials, the key components have been strengthened to withstand long periods of high-intensity use, reducing failures and prolonging service life.

5. Easy to maintain

Reasonable structural design, easy to disassemble and assemble, convenient for daily cleaning, maintenance and parts replacement, reducing maintenance costs.

6. Wide applicability

It can be applied to a variety of coating types, including water-based coatings, oil-based coatings, powder coatings, etc., and can meet the coating needs of different industries and different material surfaces.

7. Energy saving and environmental protection

Optimized paint spraying design effectively reduces the volatility and waste of paint, reduces the pollution to the environment, and also saves the cost of paint.

8. Convenient operation

Equipped with an intuitive and easy-to-understand operation interface and adjustment buttons, the operator can easily set and adjust the parameters of the spray gun and get started quickly.

9. Stable performance

Under different working environments and conditions, it can maintain a stable spraying pressure and flow rate to ensure the stability of coating quality.

4.Selling Points

1. Highly intelligent and automated

The WA-200 automatic spray gun is equipped with an advanced intelligent control system, which uses sophisticated sensors and algorithms to monitor various parameters during the spraying process in real time, such as paint flow, air pressure, gun movement speed, etc., and automatically adjust and optimize them according to the preset process requirements.

This intelligent control not only ensures the consistency and stability of each spraying, but also enables adaptive adjustment according to different workpiece shapes and paint characteristics, greatly improving the quality and efficiency of spraying. For example, in auto body painting, even if the contour and curvature of the body keeps changing, WA-200 can automatically adjust the spraying parameters to ensure uniform thickness and color of the paint surface.

2. Excellent spraying accuracy and uniformity

The spray gun's nozzle adopts a high-precision manufacturing process, which, together with the optimized airflow and paint channel design, can achieve extremely fine atomization effect, so that the paint particles are evenly distributed on the surface of the workpiece.

Its unique spray shape control technology can be adjusted to round, fan or other specific shapes as needed to meet the spraying requirements of different workpiece surfaces. For example, in the spraying of electronic equipment housings, where narrow bezels and intricate corners need to be precisely sprayed, the WA-100's precise spray control ensures that even and consistent coatings can be obtained in these areas as well.

3. Highly efficient paint delivery and utilization

Equipped with a highly efficient coating material delivery system, it is able to accurately control the amount of coating material supplied while maintaining a stable pressure, avoiding over-supply or under-supply of coating material.

The advanced atomization technology and optimized airflow design enable the paint to be fully atomized and adhere to the surface of the workpiece, reducing paint splash and waste. Compared with conventional spray guns, the WA-200 is able to significantly increase paint utilization and reduce production costs. For example, in furniture production, the use of WA-200 can save a lot of paint and reduce the environmental pollution caused by paint waste.

4. Strong adaptability and versatility

It can adapt to many different types of coatings, including water-based coatings, oil-based coatings, powder coatings, etc., and can maintain good spraying performance in coatings with different viscosities and solid contents.

In addition, the WA-200 can be seamlessly integrated with a wide range of automated equipment and production lines, whether it is a robot arm, conveyor system, or stationary station, and can easily work together to accomplish complex painting tasks. For example, in the industrial manufacturing sector, the WA-200 can be perfectly integrated with automated production lines for continuous and efficient coating of workpieces of different shapes and sizes.

5. Durable and reliable design

The gun body is made of high-strength alloy material, which is strictly heat-treated and surface-treated to provide excellent resistance to abrasion, corrosion and impact.

The key internal components are made of high quality seals and wear-resistant materials, which can maintain stable performance over a long period of time and reduce the maintenance and replacement costs of the equipment. For example, in harsh industrial environments, the WA-200 can withstand high temperatures, high humidity and corrosive gases, and still maintain reliable operation.

6. Convenient operation and maintenance

Designed with a simple and intuitive operator interface, the operator can easily set and adjust the parameters through the touch screen or control panel, and can monitor the working status of the gun and fault information in real time.

The gun is easy to disassemble and clean, and most of the components can be quickly disassembled and assembled for daily maintenance and repair. The WA-200 is also equipped with a self-cleaning function that automatically cleans the gun of residual paint at the end of a job, minimizing clogging and malfunctions. For example, during production breaks, operators can quickly complete gun maintenance to ensure that the equipment is always in optimal working condition.

7. Strict quality control and safety standards

During production, the WA-200 automatic spray gun undergoes rigorous quality inspection and testing to ensure that each gun meets high quality standards.

The gun also complies with relevant international safety standards and regulations, and is equipped with multiple safety protection devices, such as over-voltage protection, leakage protection, emergency stop button, etc., to ensure the safety of operators and the normal operation of the equipment. For example, in the event of an abnormal situation, the safety protection devices can respond quickly to avoid the occurrence and expansion of accidents.

5.Safety Precautions

1 Preparation before operation

Ensure that the working area is neat, free of debris and well ventilated to prevent the accumulation of harmful gases.

Check that the connections of the spray gun and related equipment are secure, including paint hoses and air hoses, to avoid leakage during use.

2. Personal Protective Equipment

Protective eyewear or face shield that meets standards must be worn to prevent paint from splashing into eyes and causing injury.

Wear effective respiratory protection equipment, such as gas masks or suitable masks, to filter harmful gases and paint mist.

Wear protective gloves and overalls to avoid direct skin contact with paint.

3. Precautions during operation

Set the air pressure and paint flow rate in strict accordance with the instruction manual of the spray gun. Excessive air pressure may lead to loss of control of the spray gun and splashing of paint. Maintain the proper distance and angle between the spray gun and the object being sprayed to obtain uniform coating results and to minimize paint waste and rebound. Do not point the spray gun at yourself or others during operation to prevent injury from accidental spraying.

Avoid touching the spray tip or other hot parts while the gun is in operation to avoid burns.

4. Electrical Safety

If the spray gun is electric, make sure the power supply is connected properly and there are no broken or exposed wires to prevent electric shock.

When operating in a humid environment, pay special attention to the waterproofing and insulation of electrical equipment.

5. Use of Paint and Solvents

Understand the characteristics and hazards of the paints and solvents used, and follow the relevant safety regulations for storage and handling.

Do not smoke or use open flame near the spray gun to prevent fire or explosion.

6. Equipment Maintenance and Cleaning

Turn off the power and air supply to the spray gun and related equipment before disassembling and cleaning.

When cleaning the spray gun, use appropriate cleaning agents and follow the safe operation procedures to avoid residual paint and solvent causing harm to the human body.

7. Emergency Handling

Familiarize yourself with the location of emergency exits and safety equipment in the workplace, such as fire extinguishers and emergency sprinklers.

In case of emergencies such as accidental leakage, fire or injury to personnel, stop operation immediately, take appropriate emergency measures and report to the relevant authorities in a timely manner.

Customer Concerns and FAQs

Q1: What is the WA-200 Automatic Spray Gun designed for?

A1:The WA-200 Automatic Spray Gun is engineered for high-efficiency and consistent application of coatings in industrial settings. It is ideal for tasks such as automotive painting, large-scale furniture finishing, and other coating projects requiring uniform coverage and efficiency.

Q2: How does the WA-200 Automatic Spray Gun ensure consistent performance?

A2:The WA-200 Automatic Spray Gun features a precision-engineered fluid nozzle and air cap system that provides consistent atomization and spray pattern. It also includes an adjustable trigger mechanism that allows for fine control over the application rate, ensuring uniform coating thickness across the surface.

Q3: Is the WA-200 Automatic Spray Gun easy to clean and maintain?

A3:Yes, the WA-200 Automatic Spray Gun is designed with user convenience in mind. It has a quick-disconnect feature that simplifies cleaning and maintenance. The gun's components are also designed to be easily disassembled and reassembled, making it straightforward to replace parts if necessary.

Q4: What safety precautions should I take when using the WA-200 Automatic Spray Gun?

A4:Safety is paramount when using any spray gun. Always wear appropriate personal protective equipment, such as a respirator, safety glasses, gloves, and protective clothing. Ensure that your workspace is well-ventilated to avoid inhaling paint fumes. Follow the manufacturer's safety guidelines and instructions for the best practices in operation and maintenance.

Q5: Can the WA-200 Automatic Spray Gun be used with HVLP (High Volume Low Pressure) systems?

A5:Yes, the WA-200 Automatic Spray Gun is compatible with HVLP systems, which are known for their efficiency and reduced overspray. This feature not only conserves paint but also contributes to a cleaner and more environmentally friendly painting process.

Q6: What is the warranty period for the WA-200 Automatic Spray Gun?

A6:The WA-200 Automatic Spray Gun comes with a 2-year warranty that covers any manufacturing defects. To validate the warranty, users should keep their purchase receipt and register their product with the manufacturer within the specified time frame.

Q7: How often should I replace parts on the WA-200 Automatic Spray Gun?

A7:The frequency of part replacements depends on usage and the type of paint being used. It is recommended to inspect the spray gun regularly for signs of wear, such as clogs, leaks, or diminished performance. Replace parts like the fluid nozzle, air cap, and filters as needed to maintain optimal performance. Refer to the user manual for detailed guidelines on maintenance and part replacement schedules.

Company Profile

BSS Pneumatic Tools Co., Ltd. is a leading enterprise specializing in the research and development and sales of pneumatic tools, with 15 years of industry experience. The company is committed to providing high-quality products such as air spray guns, pneumatic tools,grease injectors,and paint sprayers to meet the needs of various industries. BSS Pneumatic Tools has established a good reputation in the market with its outstanding product performance and high-quality customer service. We look forward to becoming your long-term partner in China.

Adhering to the service concept of "customer-centric," the company provides convenient and fast services through cooperation with over 1,000 distributors. The sales hotline of BSS Pneumatic Tools is 0576-86978456