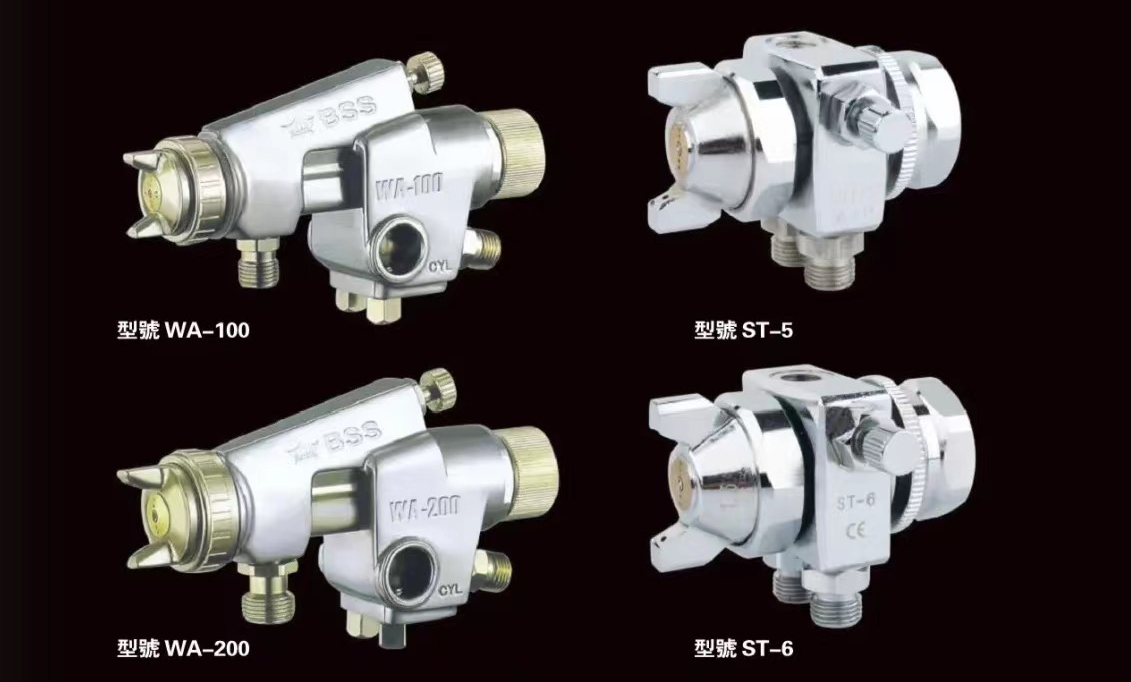

ST-5 Adjustable Pressure Feed Automatic Spray Guns

The ST-5 Automatic Spray Gun is a high performance painting tool. It utilizes advanced technology and design to achieve accurate and uniform paint spraying operations. The gun offers efficient spraying capabilities and can be adapted to a wide range of paints and work scenarios.

Product Description

Automatic Spray Guns

1.Introduction of ST-5 Adjustable Pressure Feed Automatic Spray Guns

The ST-5 automatic spray gun is a well-designed, state-of-the-art, high-end coating equipment. This gun has excellent spraying performance. Its unique nozzle design and sophisticated atomization system atomize the paint uniformly and finely, ensuring a smooth, even and highly adhesive coating on a wide range of surfaces. Whether it's complex geometries or large flat surfaces, the ST-5 can handle them with ease, providing you with high-quality coating results.

2.Parameter of ST-5 Adjustable Pressure Feed Automatic Spray Guns

|

| Technical Specification |

| Model | Coating supply system | Spray pattern | Paint nozzle diameter | Spray air pressure | Air usage | Paint discharge | Open spray | weight |

| φmm | MPa(bar) | L/min | ml/min | mm | g | |||

| ST-5 | Pressure feed | Sector and circle | 0.5 | 0.29(3.0) | 60 | 60 | 200 |

280 |

| 1.0 | 80 | 250 | 250 | |||||

| ST-6 | 1.3 | 100 | 360 | 350 | ||||

| 2.0 | 140 | 600 | 400 | |||||

| WA-100-P08 | Pressure feed | / | 0.8 | 0.29(3.0) | 270 | 150 | 190 | 480 |

| WA-100-P10 | 1.0 | 200 | 220 | |||||

| WA-100-P13 | 1.3 | 0.24(2.5) | 260 | 250 | 230 | |||

| WA-100-P15 | 1.5 | 270 | 245 | |||||

| WA-100-P18 | 1.8 | 190 530 |

310 | 240 | ||||

| WA-200-P12 | 1.2 | 0.29(3.0) | 500 | 400 | 548 | |||

| WA-200-P15 | 1.5 | 330 | 270 | 340 | ||||

| WA-200-P18 | 1.8 | 330 | ||||||

| WA-200-P20 | 2.0 | 360 | 400 | 320 330 |

||||

| WA-200-P25 | 2.5 | 500 |

3.Features

1. Superior atomization technology

- The ST-5 automatic spray gun uses an advanced atomization principle that breaks down the paint into extremely fine and uniform particles. This excellent atomization ability ensures the flatness and fineness of the coating, resulting in a smooth mirror-like finish that greatly improves the quality and aesthetics of the paint job.

- For example, in automotive painting, it is able to exhibit a highly uniform color and gloss, eliminating the possibility of orange peel.

2. Precise flow rate control

- Equipped with a high-precision flow control system, the operator can precisely set the amount of paint output. This precise control not only helps to save paint and reduce costs, but also ensures consistency from one spray to the next, minimizing problems such as uneven coating thickness caused by flow fluctuations.

- For example, when spraying electronic product housings, the ability to accurately control the thickness of the coating ensures that the assembly and performance of the product is not compromised.

3. Flexible Spray Pattern Adjustment

- The shape and range of the spray can be easily adjusted according to different painting needs. Whether it is a narrow line, a wide plane or a complex geometric shape, the ideal spray effect can be realized through the adjustment of the spray gun.

- For example, in the carved part of furniture, it can be adjusted to a narrow spray to cover the details accurately; while in the case of large tabletop painting, it is switched to a wide spray to improve the work efficiency.

4. Stabilized air pressure supply system

- An efficient air pressure regulator and stabilizer is built-in to ensure that the spray gun is supplied with stable air pressure under different working conditions. Stable air pressure is essential to maintain a stable atomization effect and paint flow, thus ensuring consistent and reliable paint quality.

- The ST-5 consistently delivers excellent spray performance, even in operating environments with fluctuating air pressure.

5. Durable Materials and Superior Craftsmanship

- The gun body and key components are made of high-strength, corrosion-resistant materials with fine machining and finishing. This gives the gun excellent durability and enables it to withstand long, intense use, reducing the frequency of repairs and replacement parts and lowering the overall cost of ownership.

- In harsh industrial painting environments, the ST-5 is able to maintain good working condition for a long time and is less susceptible to paint erosion and wear.

6. Intelligent control system

- Equipped with intelligent control interface, it can be seamlessly connected and integrated with automated painting lines or robot systems. Through programming and presetting parameters, it realizes automated and precise spraying, improving production efficiency and coating consistency.

- In large-scale industrial production, such as automotive assembly line coating, it can perfectly match with the control system of the production line to realize efficient and high-quality coating operation.

7. Easy to maintain and clean

- Reasonable design structure, easy disassembly and assembly, easy for daily maintenance and repair. Meanwhile, the channels and parts inside the spray gun are specially treated to minimize paint residue and clogging, reducing the difficulty and frequency of cleaning.

- After each use, the operator is able to clean and maintain the gun quickly and efficiently, ensuring its long-term stable performance.

Selling Points

The following is a professional introduction to the product selling points of the ST-5 automatic spray gun:

1. Advanced gun design

- The ST-5 utilizes an ergonomic gun body design that reduces operator fatigue from prolonged use. Its lightweight construction contributes to precise operation and improved work efficiency.

- For example, during long periods of furniture painting, the operator can easily hold the gun and maintain a stable spraying motion.

2. Excellent Paint Compatibility

- The product is compatible with a wide range of paints, including water-based, oil-based, and UV paints, and demonstrates a wide range of applicability.

- Whether it is metal paint used in automobile manufacturing or wood paint for the furniture industry, the ST-5 ensures high quality spraying results.

3. High-precision spraying results

- Thanks to its precision nozzle and internal structure, the ST-5 achieves micron-level spraying accuracy, ensuring that the thickness and uniformity of the coating is of an extremely high standard.

- In the case painting of electronic products, it can precisely control the thickness of the paint layer and meet the strict quality requirements.

4. Fast response and switching

- Able to respond quickly to the adjustment of spraying parameters, to achieve rapid switching from fine line spraying to large area coverage, to adapt to different painting needs.

- For example, in industrial production, from localized repair of parts to the coating of a whole batch of products, ST-5 can quickly adapt and provide stable coating results.

5. Energy-saving and environmentally friendly features

- Optimized spraying technology reduces paint waste and evaporation, lowering environmental pollution and saving production costs.

- Compared with conventional spray guns, it can significantly reduce paint consumption and exhaust emissions in mass production.

6. Stable performance with long life

- The use of high-quality materials and advanced manufacturing processes ensures that the gun maintains stable performance in harsh working environments and key components have a long service life.

- Even under high-frequency and high-intensity use conditions, such as continuous production lines in automobile factories, ST-5 can operate stably for a long time, reducing the cost of equipment maintenance and replacement.

Intelligent Monitoring and Fault Diagnosis

- Equipped with intelligent monitoring system, it can monitor the working status of the spray gun in real time, such as air pressure, paint flow, etc., and provide fault diagnosis and warning function.

- In case of abnormal situation, it can notify the operator in time to deal with it, avoiding production interruption and quality problems caused by equipment failure.

8. Easy to integrate and automate

- With good integration capability with modern automated production lines and control systems, it can realize seamless docking and enhance the automation level of overall production.

- It can perfectly cooperate with robot arms, conveyor systems and other automation equipment to realize efficient and accurate automated painting operations.

9. After-sales support and training

- Provide comprehensive after-sales technical support and training services to ensure that users can operate and maintain the spray gun correctly and give full play to its performance advantages.

- Professional after-sales team can respond to customer needs in a timely manner to solve the problems encountered in the process of use, so that users have no worries.

Safety Precautions

I. Operating Environment

1. Ensure that the operating area is well ventilated to exhaust harmful gases and paint mist generated during the spraying process.

2. Keep the operating area away from open flames, high temperature sources and flammable materials to prevent fire and explosion hazards.

II. Personal Protective Equipment (PPE)

1. The operator must wear a suitable protective mask to prevent inhalation of harmful gases and paint mist.

2. Wear protective glasses or face shield to protect eyes from paint mist and splashes.

3. Wear protective clothing, gloves and shoes to avoid direct skin contact with paint.

III. Spray gun operation

1. Before using the spray gun, carefully check that the gun is firmly connected and that there are no leaks in the air and paint hoses.

2. Set the proper air pressure and material flow rate in accordance with the spray gun's operation manual to avoid excessive pressure that could cause the spray gun to go out of control or material to splash and injure people.

3. Keep the spray gun at a safe distance from the human body and other objects to prevent injury from accidental spraying.

IV. Electrical Safety

1. If the spray gun is electrically driven, make sure the power plug and cord are intact and free of broken or exposed wires.

2. Avoid using the electric spray gun in a wet environment to prevent electrical shock.

V. Paint Storage and Handling

1. Store paint in a cool, dry, well-ventilated place away from ignition sources.

2. Properly dispose of the remaining paint and waste paint according to the instruction manual of the paint, and do not dump the paint at will.

VI. Equipment Maintenance

1. When cleaning and maintaining the spray gun, be sure to turn off the air and power supply, and wait until the spray gun cools down.

2. When disassembling and installing gun parts, operate carefully to avoid injury from ejected parts.

VII. Emergency Response

1. Familiarize yourself with the location of emergency exits and fire extinguishing equipment near your workplace.

2. In the event of an emergency such as fire, explosion, or injury, stop operation immediately and activate the emergency plan.

Customer Concerns and FAQs

Q1: What is the ST-5 Automatic Spray Gun designed for?

A1:The ST-5 Automatic Spray Gun is engineered for precision coating applications in various industries, including automotive, furniture, and general industrial finishing. It is designed to provide consistent and accurate spray patterns for a professional finish.

Q2: How does the ST-5 Automatic Spray Gun ensure consistent performance?

A2:The ST-5 Automatic Spray Gun features a high-quality fluid nozzle and air cap system that ensures consistent atomization and spray pattern. It also includes an adjustable trigger mechanism that allows for fine control over the application rate, ensuring uniform coating thickness across the surface.

Q3: Is the ST-5 Automatic Spray Gun easy to clean and maintain?

A3:Yes, the ST-5 Automatic Spray Gun is designed with user convenience in mind. It has a quick-disconnect feature that simplifies cleaning and maintenance. The gun's components are also designed to be easily disassembled and reassembled, making it straightforward to replace parts if necessary.

Q4: What safety precautions should I take when using the ST-5 Automatic Spray Gun?

A4:Safety is paramount when using any spray gun. Always wear appropriate personal protective equipment, such as a respirator, safety glasses, gloves, and protective clothing. Ensure that your workspace is well-ventilated to avoid inhaling paint fumes. Follow the manufacturer's safety guidelines and instructions for the best practices in operation and maintenance.

Q5: Can the ST-5 Automatic Spray Gun be used with HVLP (High Volume Low Pressure) systems?

A5:Yes, the ST-5 Automatic Spray Gun is compatible with HVLP systems, which are known for their efficiency and reduced overspray. This feature not only conserves paint but also contributes to a cleaner and more environmentally friendly painting process.

Q6: How often should I replace parts on the ST-5 Automatic Spray Gun?

A6:The frequency of part replacements depends on usage and the type of paint being used. It is recommended to inspect the spray gun regularly for signs of wear, such as clogs, leaks, or diminished performance. Replace parts like the fluid nozzle, air cap, and filters as needed to maintain optimal performance. Refer to the user manual for detailed guidelines on maintenance and part replacement schedules.

Company Profile

BSS Pneumatic Tools Co., Ltd. is a leading enterprise specializing in the research and development and sales of pneumatic tools, with 15 years of industry experience. The company is committed to providing high-quality products such as air spray guns, pneumatic tools,grease injectors,and paint sprayers to meet the needs of various industries. BSS Pneumatic Tools has established a good reputation in the market with its outstanding product performance and high-quality customer service. We look forward to becoming your long-term partner in China.

Adhering to the service concept of "customer-centric," the company provides convenient and fast services through cooperation with over 1,000 distributors. The sales hotline of BSS Pneumatic Tools is 0576-86978456